|

一.Introduction to the spring actuator ring

PTFE seals spring actuator is assembled within a U-PTFE seals special spring performance. With the appropriate spring force by the fluid pressure system, to the top of the sealing lip and gently press and hold the sealed surface to produce a very good sealing effect. The sealing lip has the best characteristics of a short, thick, thus reducing friction and longer life.

PTFE is an excellent chemical resistance, heat resistance and good sealing material that can be applied to the vast majority of chemical fluids, solvents, and hydraulic oil, lubricating oil, the compression set is small so it can be long-term sealing performance of play .

Refrigerant temperature range can be used to 300 ℃, pressure from vacuum to high pressure 700kg/cm2 (about 70MPa), moving at speeds up to 20m / s. Spring can be used for different environments, made of stainless steel, corrosion resistant alloys, it can be used in a variety of high temperature corrosion fluid situations.

1.5mm diameter can be made to the 1.5m of the coil by Run Lion, and existing customers are using the 1.5mm spring ring.

Second, the main application

Typical applications are as follows:

☆ loading and unloading arm rotary joint seals with axial

☆ spray paint or other paint system valves seals

☆ vacuum seals

☆ drinks, water, beer, installations and equipment (such as the device valve) and the food industry seals

☆ hydraulic cylinder rod seal is the best substitute, especially for high-pressure, high lateral loads, high speed, low friction, rotary applications where a large deflection

☆ petrochemical, equipment, application of static and dynamic seals

☆ automotive, aerospace industrial seals (low friction, long life)

☆ other industrial equipment or pressure vessel seals

Third, the spring actuator ring advantages

☆ sealing performance without the impact of lack of lubrication at start

☆ effectively reduce the wear and friction

☆ by different sealing materials and spring mix, can show different sealing force to suit all application requirements

☆ made using special CNC processing machines, no mold costs - especially for a small variety of ring

☆ chemical corrosion and heat resistance than the commonly used rubber ring excellent dimensional stability, no distortion or contraction of the volume generated by the sealing performance deterioration problem

☆ compact structure, can be installed in a standard O-ring groove

☆ substantial increase in capacity and service life of seals

☆ ring groove can be filled with anti-pollution materials

☆ by sealing material for the PTFE (polytetrafluoroethylene), very clean, does not pollute the process

☆ low coefficient of friction, no hysteresis effect slip

☆ start small frictional resistance, even if down a long time or intermittent operation, able to maintain a low power performance from

Fourth, the spring actuator ring style

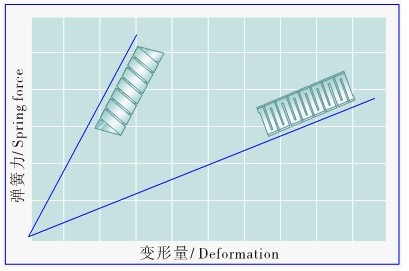

Spring actuated seals or external pressure, static and dynamic variety of applications, the choice of V-or H-form and the spring lip seal design, which show the sealing force and the compressibility of the different deformation (as shown).

V-spring / cantilever spring

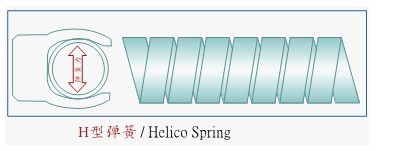

H-spring / coil spring

The size will affect the spring force spring actuator ring seal properties, friction and wear behavior; the spring determines the compressibility of the spring actuator ring for the seal lip and seal groove wear ability to compensate variation of dimensional tolerances.

V-spring actuator ring features

☆ V-type spring actuator for static seals PTFE seals and reciprocating seals occasions

☆ dynamic sealing lip thickness increases, giving it a longer life

☆ This structure reduces the seal dynamic sealing surface contact area, thereby reducing the friction

☆ resistance temperature range: -150 ℃ to 260 ℃

☆ standard applies to pressure from vacuum to 210 kg / cm ², and the installation of special ring shape may be resistant to care back to 700 kg / cm ²

Applications

☆ body axis reciprocating piston seal

☆ back to the shaft seal, speeds of up to 4M / s

☆ static seal, seals may allow greater tolerance with the unscrupulous

☆ face seal for internal pressure or external pressure application environment

☆ dynamic seals for temperatures up to 260 ℃

H-spring actuator ring features

☆ spring constant high, suitable for medium and high load applications

☆ scroll every lap average spring force

☆ can replace the standard British O-ring groove size without modifying the

☆ stainless steel spring, corrosion-resistant alloys can also be used

☆ resistance temperature range: -150 ℃ to 300 ℃

☆ standard applies to pressure from vacuum to 210 kg / cm ², and the installation of special ring shape may be resistant to care back to 700 kg / cm ².

☆ tolerance does not apply to larger and poor seals on the heart

Applications

☆ static seals under the shaft and piston

☆ slow dynamic seal where the speed is lower than 3 mpm

☆ internal and external pressure with the surface of the seal

☆ vacuum seal with the refrigerant

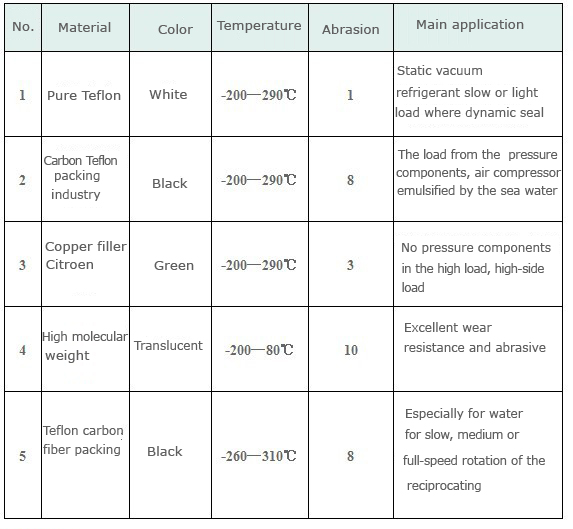

The choice of sealing materials

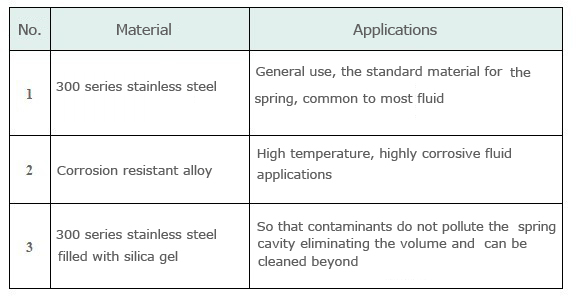

Spring Material

Installation - Installation on the open seals

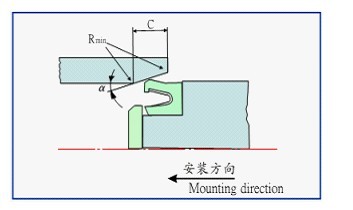

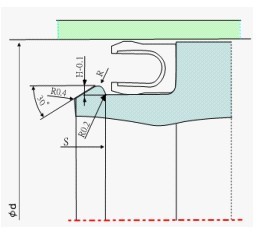

Piston seals installed in open trench, install the seal lip facing direction, the front chamfer dimensions as shown above, all acute angle must rounding R = 0.5mm.

Piston seals installed in open trench, install the seal lip facing direction, the front chamfer dimensions as shown above, all acute angle must rounding R = 0.5mm.

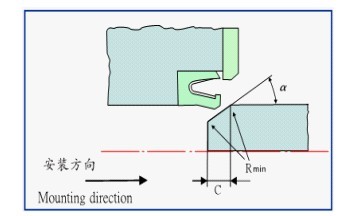

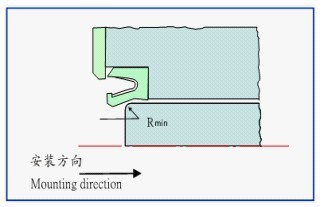

Shaft seals installed in open trench, install the seal lip facing direction, the front chamfer dimensions as shown above, all acute angle must rounding R = 0.5mm.

Shaft seals installed in open trench, install the seal lip back direction, the front chamfer dimensions as shown above, all acute angle must rounding R = 1.0mm.

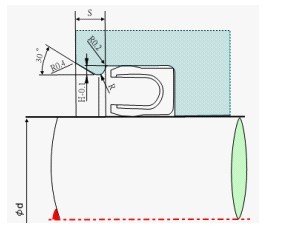

Installation - Installation of the embedded-type seals

Piston rod

Piston

|